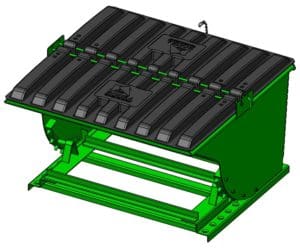

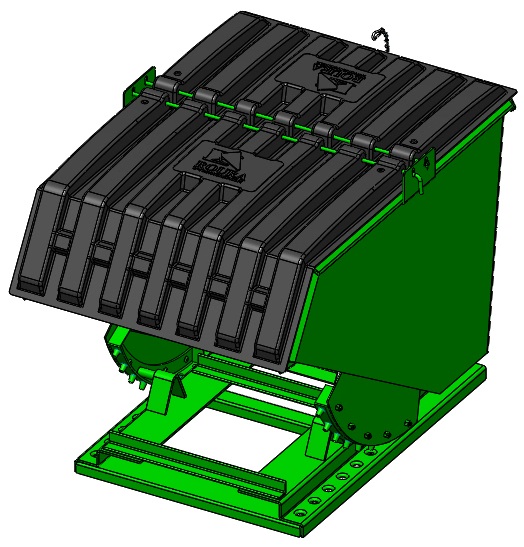

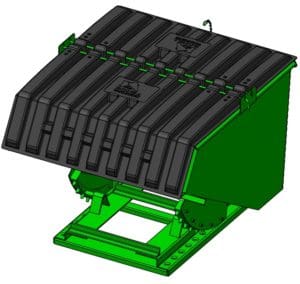

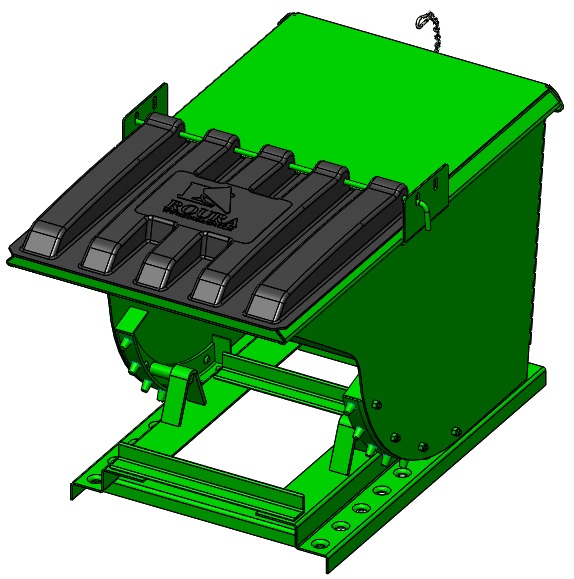

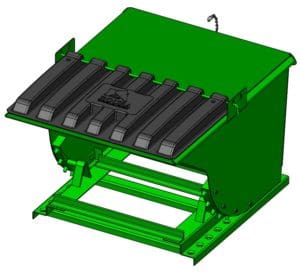

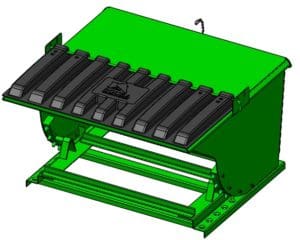

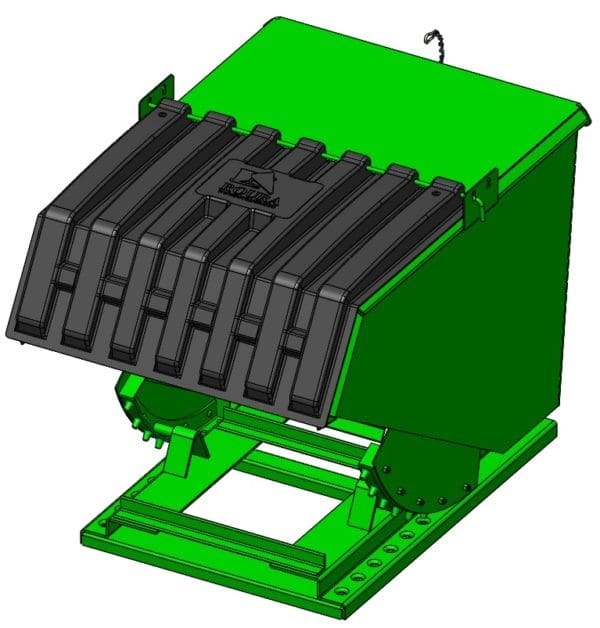

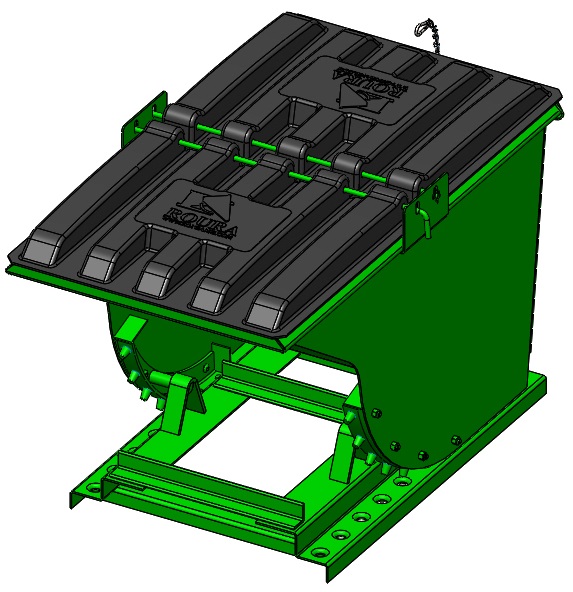

Plastic Lid Self-Dumping Hoppers

- Step 1: Browse through our products below

- Step 2: Select a model and customize by selecting from available options

- Step 3: Add it to your quote cart and select additional models or

- Step 4: Checkout by clicking “Quote Cart” or the cart icon in the top right menu

Roura’s Durable self-dumping hoppers are available from 1/2 cubic yard through 2 1/2 cubic yards to solve all material handling requirements. Steel lid options are available based on storage needs.

Showing all 12 results

-

H-PLDA-135

Load Capacity: 4,000 lbs. Volume Capacity: 1/2 cu. yd. Dimensions: 57" x 34 1/2" x 36 1/2"Read more -

H-PLDA-205

Load Capacity: 6,000 lbs. Volume Capacity: 3/4 cu. yd. Dimensions: 57" x 46 1/2" x 36 1/2"Read more -

H-PLDA-270

Load Capacity: 6,000 lbs. Volume Capacity: 1 cu. yd. Dimensions: 57" x 58 1/2" x 36 1/2"Read more -

H-PLDA-410

Load Capacity: 6,000 lbs. Volume Capacity: 1 1/2 cu. yd. Dimensions: 65" x 47" x 49"Read more -

H-PLDA-540

Load Capacity: 6,000 lbs. Volume Capacity: 2 cu. yd. Dimensions: 65" x 60" x 49"Read more -

H-PLDA-675

Load Capacity: 6,000 lbs. Volume Capacity: 2 1/2 cu. yd. Dimensions: 65" x 76 1/2" x 49"Read more -

H-PLDB-135

Load Capacity: 4,000 lbs. Volume Capacity: 1/2 cu. yd. Dimensions: 57" x 34 1/2" x 36 1/2"Read more -

H-PLDB-205

Load Capacity: 6,000 lbs. Volume Capacity: 3/4 cu. yd. Dimensions: 57" x 46 1/2" x 36 1/2"Read more -

H-PLDB-270

Load Capacity: 6,000 lbs. Volume Capacity: 1 cu. yd. Dimensions: 57" x 58 1/2" x 36 1/2"Read more -

H-PLDB-410

Load Capacity: 6,000 lbs. Volume Capacity: 1 1/2 cu. yd. Dimensions: 65" x 47" x 49"Read more -

H-PLDB-540

Load Capacity: 6,000 lbs. Volume Capacity: 2 cu. yd. Dimensions: 65" x 60" x 49"Read more -

H-PLDB-675

Load Capacity: 6,000 lbs. Volume Capacity: 2 1/2 cu. yd. Dimensions: 65" x 76 1/2" x 49"Read more