RDR-1D

Help Me Choose:MHR System (Mechanical Hopper Release)

MHR System - Left Hand Model

Used with forklift trucks that allow the operator to mount and dismount from the right side.

MHR System - Right Hand Model

Used with forklift trucks that allow the operator to mount and dismount from the left side.

View MHR Demonstration

Help Me Choose:Handle System

Pull-Down Handle (Left Hand Model Shown)

This option is the perfect application used when the hopper is at an elevated dumping height. Simply pull the superior built cable system while standing on the ground to dump those loads at elevated heights. The cable system is stored on the back of the hopper, providing a safe environment while the hopper is in its filled operation.

View Pull-Down Handle Demonstration

Auto-Latch Handle (Right Hand Model Shown)

Roura’s Auto-Latch handle option provides a safe and efficient method of dumping bulk material content from our hoppers. Its auto secure handle feature allows the locking position of the handle to be fully engaged to the hopper until the handle is tripped to dump the content. Our exclusive internal stop pin on the Roura Auto-Latch handle is designed to minimize the number of parts resulting in the reduction of possible pinch point areas of the dumping operation.

View Auto-Latch Demonstration

Help Me Choose:Casters/Wheels

Caster Options

Roura provides caster and wheel sets in a variety of combinations to fit your specific needs. A complete set includes two swivel rear casters and two rigid front casters. All swivel wheels shown are mounted on kingpinless swivel rigs. The following information will allow you to choose the right type, size and rig combination.

Click here for more details

Help Me Choose:Covers

Watertight Steel Cover: Type A

Watertight Steel Cover: Type A - Center hinge opens front & back (not recommended on models 680+).

Watertight Steel Cover: Type B

Watertight Steel Cover: Type B - Center hinge fixed back (not recommended on models 680+).

Watertight Steel Cover: Type D

Watertight Steel Cover: Type D - Double hinge cover w/ fixed center (used on models 680 thru 1500).

Vinyl Tarp

Waterproof tarp cover, fitted front with bungee cord fasteners in back.

Mesh Tarp

The mesh tarp has a fitted front with bungee cord fasteners in back.

Help Me Choose:Bases

Standard Fork Entry Base

Roura manufactures two basic designs of hopper bases. Our open channel bases are standard on all Durable model hoppers, and 2 ½ cu. yd. and smaller Rugged and Ultimate Strength hoppers. These bases are constructed with 1/4" thick track on all one ton (1T) and two ton (2T) models and 5/16" track for all hoppers over two tons (3T through 5T).

Ultimate Strength Heavy Duty Boxed Tube Base

Our boxed tube design is standard on all 3 cu. yd. and larger Rugged and Ultimate Strength hoppers and optional on all other two ton (2T) and three ton (3T) models. This design is constructed from 1/4" plate steel on all ½ cu. yd. and smaller hoppers and 5/16" tube for 1 cu. yd. and larger. This base design is unique to the industry and provides superior durability for heavy load applications as well as resistance to aggressive handling.

Three-Way Base Entry

The three way base entry allows the operator to enter the hopper from three sides.

Base Legs

Supports the hopper at an elevated height. The height of the base legs are available in 4"-12".

Help Me Choose:Band Cutter

Roura’s Band Cutter option is a safe and efficient way to dispose of your used banding material issues. Simply insert the steel banding into the mounted Roura banding option and cut those long and dangerous lengths of banding material into the scrap hopper.

View Band Cutter Demonstration

Band Cutter - Left Hand Option

Band Cutter mounted on the left side.

Band Cutter - Right Hand Option

Band Cutter mounted on the right side.

Help Me Choose:Band Cutter

Roura’s Band Cutter option is a safe and efficient way to dispose of your used banding material issues. Simply insert the steel banding into the mounted Roura banding option and cut those long and dangerous lengths of banding material into the scrap rotator box.

View Band Cutter Demonstration

Band Cutter - Left Hand Option

Band Cutter mounted on the left side.

Band Cutter - Right Hand Option

Band Cutter mounted on the right side.

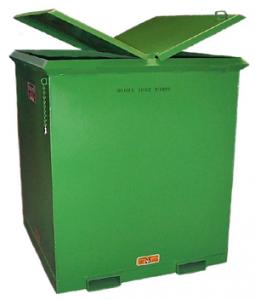

Help Me Choose:Colors

Paint Colors

All paint is enamel on steel without primer. Safety green is our standard color on all hoppers and containers unless otherwise specified. All containers are marked with a product label identifying “Customer”, City and State”, and “PO number” on the upper left corner of the rear of the container and inside center of the front of the container. Please call for special colors, markings, and custom identification requirements. The following colors may be ordered on line: (Actual colors may vary.)

Click here for more details

Help Me Choose:Covers

Watertight Steel Cover Type-A

14 gauge center hinged cover with a continuous hinge across the top of the cover. Drain channel under hinge.(Models 680 and larger have 12 gauge Covers) 1/4” neoprene gasket attached to bottom of cover. Cover is watertight. (1) chest handle on each cover. Hopper to have(1)D-ring, chain and snap hook mounted to hopper to hold cover when dumping.

Vinyl Tarp

Vinyl waterproof tarp. Helps to comply with rainwater runoff environmental regulations.

Mesh Tarp

Prevents material from falling out of box during transport.

Dust Cover Vinyl Tarp

Fits over the top of the box and is secured with an elastic cord.

Dust Cover Mesh Tarp

Fits over the top of the box and is secured with an elastic cord.

Help Me Choose:Bases

Bases

The four-way entry option allows the forklift operator to pick up the rotator box from all sides.

Help Me Choose:Push Handle

Mounted on to the back of the hopper to allow manual positioning.

Help Me Choose:Crane Eyes

(4) crane eyes & (2) base to body chains per hopper. The chains keep the base attached to the body when lifting hopper using the crane eyes.

Help Me Choose:Mast Secure Chain

The chain secures the hopper to the forklift truck. (1) Ø 5/16" chain, (1) grab hook, (1) chain support bracket.

Help Me Choose:Base Legs

Base Legs, for use with pallet jacks. Specify height (from 4" to 12") desired in comments section.

Help Me Choose:Floor Lock

Floor lock.

Help Me Choose:Hasps

Hasp for Locking Cover(s) Boxes with dual center hinged steel cover with HASP option will require (2) HASPS.

Help Me Choose:Slide Bolt Latch

The slide bolt latch provides a secure lock to prevent the hopper from dumping.

Help Me Choose:Drain w/ Plug

Help Me Choose:Base-to-Body Chains

TWO 5/16" base-to-body chains.

Help Me Choose:Wheel Brakes

Available on all models.

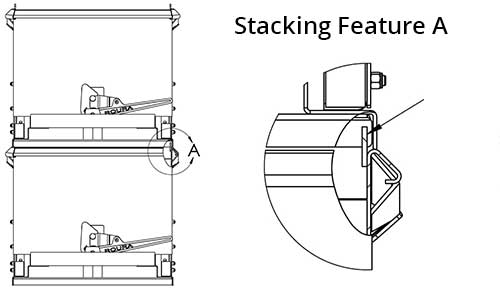

Help Me Choose:Stacking Feature

Help Me Choose:Rubber Cushion

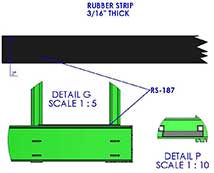

The Roura Slab & Remnant rack rubber cushion option ( RS-187 & RS-093 ) is designed to provide addition protection to the slab and remnant products.

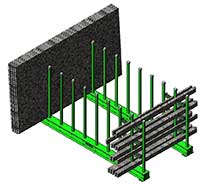

Help Me Choose:Backsplash Rack

The Roura optional backsplash bracket set ( RSR-60-BSP ) is designed to hold long lengths of remnant backsplash product on the slab racks. The RSR-60-BSP comes with two 60” tall steel fabricated brackets that are welded together for superior strength. Rubber cushion protection is applied to all shelf arms to protect finish edges. The brackets come in a set of 2 that fit perfectly into all Roura slab racks.

Help Me Choose:Hinged Door Option

Hinged Door Option. Makes it easier to reach low stock or dropped items.

Help Me Choose:Four-Way Entry Base

The four-way entry option allows the forklift operator to pick up the rotator box from all sides.

Help Me Choose:Stacking Feature

Stacking Feature for Rotator Boxes.

Help Me Choose:Additional Cross-Member

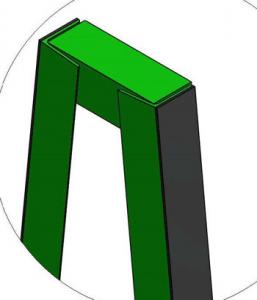

An additional A-Frame cross-member option is available for purchase for unique specific requirements.

Help Me Choose:A-Frame Rubber Cushion

The Roura optional A-frame rubber cushion (RSR-093) is designed to provide addition protection to the slab products.

Help Me Choose:Upper Storage Tray

Roura manufactures 2 different size storage tray options for our stand A-Frame (RAF-60). The upper storage tray (RAF-60-UT) and the lower storage tray (RAF-60-LT) are designed to mount inside of the A-Frame unit to hold backsplash remnants. This option is a great floor space saver and provides additional storage protection for backsplash remnants. Each tray is sold separately.

Help Me Choose:Lower Storage Tray

Roura manufactures 2 different size storage tray options for our stand A-Frame (RAF-60). The upper storage tray (RAF-60-UT) and the lower storage tray (RAF-60-LT) are designed to mount inside of the A-Frame unit to hold backsplash remnants. This option is a great floor space saver and provides additional storage protection for backsplash remnants. Each tray is sold separately.

Help Me Choose:Upper & Lower Storage Trays

Roura manufactures 2 different size storage tray options for our stand A-Frame (RAF-60). The upper storage tray (RAF-60-UT) and the lower storage tray (RAF-60-LT) are designed to mount inside of the A-Frame unit to hold backsplash remnants. This option is a great floor space saver and provides additional storage protection for backsplash remnants. Each tray is sold separately.

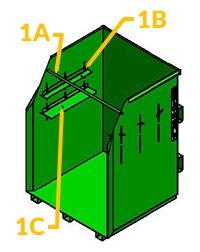

Help Me Choose:Gaylord Rotator Options

This round bar provides extra strength to the open end container. Each end is welded to the side wall of the container.

1B - Standard Adjustable RailThis is the standard part that is sold with each unit (1 set per unit).

1C - Optional Wider Adjustable RailThis is an upgradable option that provides a wider support rail (1 set per unit).