What Are the Different Types of Caster Wheels?

October 10, 2024This blog covers the different types and styles of caster wheels and guidance on how to select the right one.

This blog covers the different types and styles of caster wheels and guidance on how to select the right one.

This blog covers various factors to consider when selecting a self-dumping hopper, including weight capacity, hopper material, and more.

Stone transportation is a tough, dangerous job. Stone and granite slabs or scants can weigh thousands of pounds and can cause fatal injuries if mishandled. To reduce injury risks and potential machinery damage, it’s important to not only have a material handling safety plan in place, but to also invest in the right stone handling equipment.

Stone Transport & Handling Options

At Roura, we offer two material handling options that can be used to transport stone and granite: open-sided hoppers and A-frames.

Let’s look closer.

As the name suggests, open-sided hoppers are containers/storage hoppers that do not feature any closed ends;

When companies look to upgrade their bulk material handling processes and capabilities, they invariably come face-to-face with choosing between an industrial-strength storage hopper or a bin. The goal is to have a safe, secure, and reliable means of storing, moving, transporting, and unloading end-of-shift or end-of-day scrap metal, trash, or refuse. One solution is safe and easy to use while the other can often put employees at risk of injury.

Keep reading to learn more.

What Is the Difference Between a Hopper & Bin?

It’s not uncommon to hear people use hoppers and bins interchangeably. However,

Skeleton Hoppers are bulk material containers used to haul and discharge various materials during sheet metal operations. If you’re looking for Skeleton Hoppers, look no further than Roura. We’re an industry-leading steel fabricator that specializes in manufacturing durable bulk material containers.

Keep reading to learn more about our line of Skeleton Hoppers, or contact us today to request a quote.

Which Model Do You Need?

Our Skeleton Hoppers are perfectly balanced, built to withstand heavy use, and capable of holding up to 6,000 pounds of sheet metal. Plus, they’re easy to operate. All you have to do is pull the heavy-duty handle to discharge the load,

Always follow our safety instructions before using drum handling equipment. These products are specifically designed to secure a drum before lifting, moving and dumping it into a larger container. While our drum lifter design is suitable for use with standard forklifts equipment, always review your equipment before use. This ensures your forklift is capable of handling the weight and rotating requirements of your new drum rotator.

Storing and Transporting

Once you place a drum in your Roura Material Handling drum rotator, you can easily transport it around your facility. Unlike a drum attachment on your forklift, our drum rotator allows you to move a barrel without removing your forklift forks or using a separate attachment.

Some facilities and plants may require the transportation of hazardous goods. When it comes to transporting hazardous goods, you must be extremely careful. To reduce risks of contamination, injury, or product damage, we recommend using a self-dumping forklift dumpster, or hopper, to transport your materials.

If you’ve never used a forklift hopper to safely handle hazardous materials, keep reading this article. In this blog post, we’ll go over important safety tips and how you can integrate these dumpsters into your existing safety plans or programs.

Tips to Help You Stay Safe When Transporting Hazardous Goods

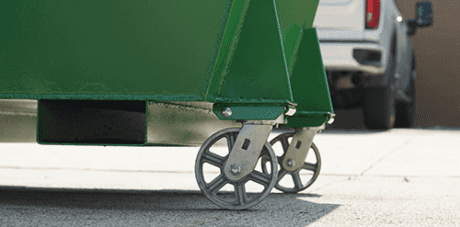

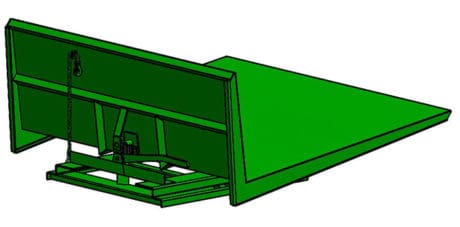

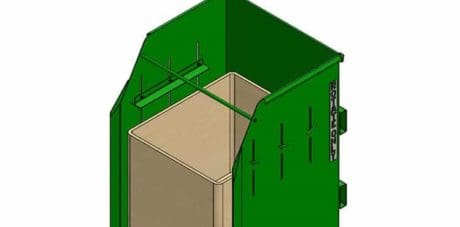

In this quick guide, you’ll learn how to install caster wheels onto a Roura self-dumping hopper. The process is quick and easy!

What Is A Gaylord Rotator?How Do You Safely Operate A Forklift Gaylord Rotator?

The operator picks up a corrugated box full of material and takes the box to the Roura Gaylord rotator’s location. The RGR includes a flared reinforced opening feature. The forklift operator guides the corrugated box into the RGR. The forklift operator should then place the corrugated box into the RGR then back up away a safe distance from the container to disengage the RGR. The forklift operator should then lower the forks to the ground.

A Gaylord rotator is a machine that we specifically designed so that it can transfer materials effectively and safely by removing them from containers.

Everyone in the manufacturing industry knows the importance of hauling products and materials and removing waste efficiently. But, unfortunately, one of the most prominent problems workers encounter is operating effectively in a cluttered space full of trash and parts they don’t need.

However, a light at the end of the tunnel provides an excellent solution: The self dumping hopper. These practical yet useful hoppers allow manufacturing facilities to have a sound business operation without worrying how materials, scrap, and trash will be moved and stored.

How Do Dump Hoppers Work?

The basic concept of a dumpster hopper is an easy way to collect materials in a large container that will either be moved or disposed of.