Always follow our safety instructions before using drum handling equipment. These products are specifically designed to secure a drum before lifting, moving and dumping it into a larger container. While our drum lifter design is suitable for use with standard forklifts equipment, always review your equipment before use. This ensures your forklift is capable of handling the weight and rotating requirements of your new drum rotator.

Storing and Transporting

Once you place a drum in your Roura Material Handling drum rotator, you can easily transport it around your facility. Unlike a drum attachment on your forklift, our drum rotator allows you to move a barrel without removing your forklift forks or using a separate attachment. Simply connect the safety rails and secure the safety chain. You can leave a barrel stored in the rotator and lift it using the included forklift channels.

Lifting and Dumping

Review our operational videos for our drum rotator products before attempting to lift and dump your hopper. Once the drum is fully secured, maneuver your forklift forks into the channels underneath the drum handling equipment. Lift it to a safe distance above the ground before moving it to a new location.

To dump your hopper, place it back on the ground and remove the forklift forks. Tilt the forks and secure them in the tilting channels located on the side of your drum lifter. You can pick up and tilt the unit from this position. Once the drum is fully emptied, carefully tilt it back to an upright position and bring it to rest on the ground. Remove the safety chain and loosen the adjustable guards before removing the empty barrel.

Common Applications

Our team at Roura Material Handling is proud to offer hoppers and rotators that help you handle materials around your workplace. Review these common applications for barrel tilting products and consider how you can improve the efficiency of your company with drum handling equipment.

Food Service

There are many food service uses for 55 gallon drums. These versatile barrels are used to store cooking oil and other food-grade items. Once you’ve emptied a barrel, it’s common to use the old barrel to store used oil. Use our drum handling equipment to lift, maneuver and dump spent oil into a larger reservoir before removing it from your property.

Scrap Removal

Loose scrap materials may be easier to store in a drum than a full-size hopper. If you store scrap metal, loose pieces of aggregate or other refuse in a drum, our drum lifter and tilter is an excellent way to improve the efficiency of your scrap removal process. These heavy materials may quickly overload a hopper, but sturdy drum lifters can lift up to 6,000 pounds.

Recycling

Manage your facilities recycling with barrel lifting equipment by Roura Material Handling. Unused barrels are a great option for recycling containers around your facility. These small containers can be used by employees and customers to dispose of trash or recyclable materials. Once full, a 55 gallon barrel can be easily picked up with a forklift and placed in a drum tilter to be emptied into a larger recycling container.

Roura Drum Operating Instructions

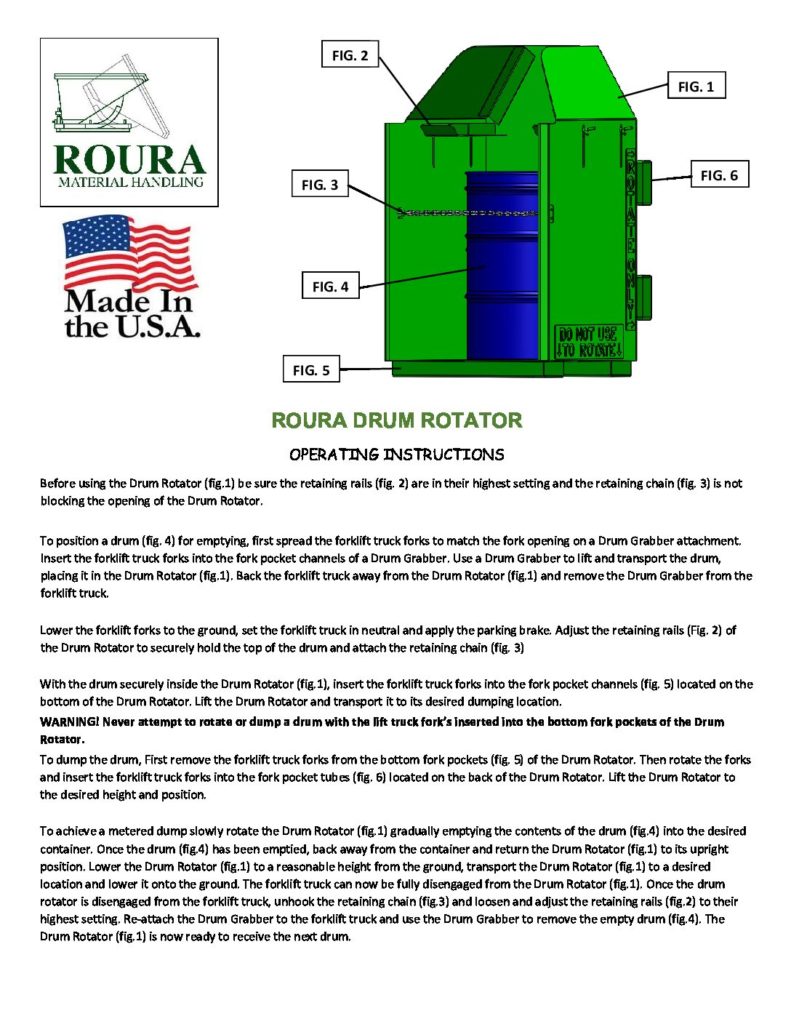

Before using the Drum Rotator (fig.1) be sure the retailing rails (fig.2) are in their highest setting and the retailing chain (fig.3) is not blocking the opening of the Drum Rotator.

To position a drum (fig.4) for emptying, first spread the forklift truck forks to match the fork opening on a Drum Grabber attachment. Insert the forklift truck forks into the fork pocket channels of a Drum Grabber. Use a Drum Grabber to lift and transport the drum, placing it in the Drum Rotator (fig.1). Back the forklift truck away from the Drum Rotator (fig.1) and remove the Drum Grabber from the forklift truck.

Lower the forklift forks to the ground, set the forklift truck in neutral and apply the parking brake. Adjust the retaining rails (fig.2) of the Drum Rotator to securely hold the top of the drum and attach the retaining chain (fig.3).

With the drum securely inside the Drum Rotator (fig.1) insert the forklift truck forks into the fork pocket channels (fig.5) located on the bottom of the Drum Rotator. Lift the Drum Rotator and transport it to the desired dumping location.

WARNING! Never attempt to rotate or dump a drum with the lift truck fork’s inserted into the bottom fork pockets of the Drum Rotator.

To dump the drum, first remove the forklift truck forks from the bottom of the fork pockets (fig.5) of the Drum Rotator. Then rotate the forks and insert the forklift trucks forks into the fork pocket tubes (fig.6) located on the back of the Drum Rotator. Lift the Drum Rotator to the desired height and position.

To achieve a metered dump, slowly rotate the Drum Rotator (rig.1) gradually emptying the contents of the drum (fig. 4) into the desired container. Once the drum (fig.4) has been emptied, back away from the container and return the Drum Rotator (fig.1) to its upright position. Lower the Drum Rotator (fig.1) to a reasonable height from the ground, transport the Drum Rotator (fig.1) to the desired location and lower it onto the ground. The forklift truck can now be fully disengaged from the Drum Rotator (fig.1). Once the drum rotator is disengaged from the forklift truck, unhook the retaining chain (fig.3) and loosen and adjust the retaining rails (fig.2) to their highest setting. Re-attach the Drum Grabber to the forklift truck and use the Drum Grabber to remove the empty drum (fig.4). The Drum Rotator (fig.1) is now ready to receive the next drum.