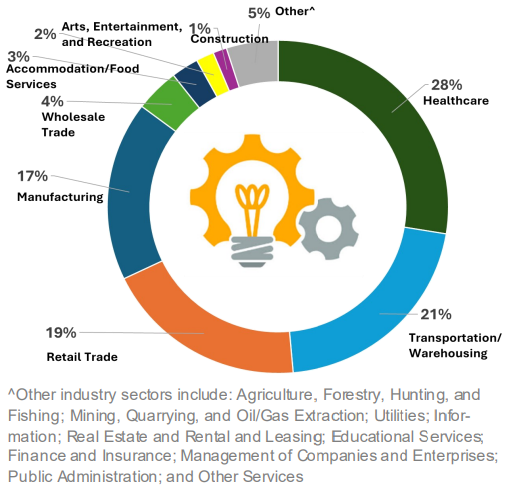

Any employee required to handle materials, whether they’re construction workers, package handlers, or forklift operators, faces a higher risk of accidents and injuries, including injuries from fallen objects, respiratory injuries from debris, and machinery and equipment incidents. In 2023, OSHA even reported 5,283 fatal work injuries. Among the industries submitting reports, manufacturing, retail, healthcare, transportation/warehousing, and construction had the highest number of injury reports.

Workplace Safety Starts at the Top

Workplace safety always begins at the top. One immediate step employers can take to reduce on-site injuries is to create stringent material handling requirements and provide comprehensive safety training to any employee required to stack and store materials, as well as any employee using material handling equipment like forklifts. Employees should also know, understand, and comply with all federal and state OSHA requirements.

What to Include in a Safety Plan

Required Equipment

Any employee expected to handle materials should have the following protective equipment:

- Gloves or hand protectors

- Steel-toed safety boots

- Handles and holders to move loads

- Eye protection when opening a wire-bound box

- Band cutter to break down packaging materials

- Self dumping hoppers to store debris and broken-down packaging materials

- Tools for moving and lifting heavy or large loads

- Granite racks or a granite A-Frame to safely and securely store large slabs of rock or granite

In your safety plan, we recommend setting an expectation that workers are not to handle any equipment if they don’t have this equipment or aren’t trained to use it.

Safe Stacking & Storage Rules

In Standard 1910.176(b), OSHA states: “Storage of material shall not create a hazard. Bags, containers, bundles, etc., stored in tiers shall be stacked, blocked, interlocked, and limited in height so that they are stable and secure against sliding or collapse.” This is a good rule to follow.

No matter what type of material is being stacked, there are standard guidelines that can help employees stay safe:

- Don’t block emergency exits or equipment, such as fire alarms, when stacking materials.

- Make sure that there is sufficient clearance around stacks for easy access.

- Observe stacking limitations; the height-to-base ratio should not exceed 3:1.

- Ensure stacks are self-supporting and stable.

- Leave clearance between stacks and the heating pipes, lights, and sprinkler heads.

- Boxes should be placed on a pallet for better security and stability.

- Band the boxes together with shrink wrap or banding to increase stability.

- Bags, sacks, and bundled materials should not be stacked closer than 18 inches to the walls or sprinklers.

- Interlock the rows for more security and stability.

- Do not stack or store pipes in a way that could cause them to spread or tilt unless the materials are in racks.

- The racks that store these materials should not face the main aisles, which creates hazards for workers removing other supplies.

General Safety Tips

Employees should know how to stack materials safely, but there are also some key safety tips you’ll want to highlight in your material handling guidelines, including:

- Always check the material for nails, jagged edges, slippery surfaces, or other protruding objects.

- Make sure a good grip can be obtained on the object before moving.

- Watch for pinch points (where fingers might be squished between two heavy objects).

- Keep hands away from the ends of long objects, such as lumber or pipe, to prevent injuries and pinching.

- Keep hands and gloves free of oil or grease.

- Wipe off objects before handling or storing them if they are wet or oily.

Transporting Objects

Back injuries are the most common injury that can occur when lifting materials and are often caused when employees overexert themselves or don’t follow proper lifting guidelines. These injuries can lead to severe muscle strains, resulting in employees missing weeks, months, or even years of work.

To prevent these injuries, enforce a debris-free, well-lit workspace. Employees should always watch for liquid, cables, wires, or other hazards on the floor. Your employees should also be trained on how to properly lift boxes and avoid methods that can cause injuries, such as lifting boxes from a sitting position, lifting packages directly from the floor, keeping the box close to the chest, and lifting heavy boxes over or around obstructions.

Employees should also never be asked to carry boxes long distances, so in your guidelines, define a maximum length of transit and maximum weight for boxes that must be handled manually. Otherwise, use hand-held tuggers, trolleys, and carts to transport heavy loads and ensure there are clear paths to and from various locations across your site.

Improve Workplace Safety With Help From Roura

Creating material handling requirements is just one step to workplace safety—the other is ensuring you’re investing in equipment designed to improve material handling safety.

Roura Material Handling specializes in engineering custom self-dumping hoppers for businesses in many industries, ranging from manufacturing and machining to construction, agriculture, and waste management. We know how dangerous material handling can be, and because of this, we’ve included many safety features on our hoppers, including plastic lids to safeguard workers from debris, a mechanical hopper release system that allows operators to dump materials without leaving their forklift, and auto-latch handles, trip lever handles, mast-secure chains, and slide bolt latches.

To improve internal safety planning and training, we also have a wealth of safety-related resources on our website on how to use our products.

If you’re interested in building a safer workplace for your employees, contact Roura today to speak with one of our product specialists.