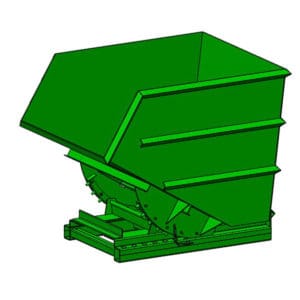

Workplace clutter consisting of scraps of wood or metal can cause injuries due to tripping or gouging. A self dumping steel hopper provides you with a place to dispose of such materials quickly and easily, making it less likely that they will accumulate around the work area. Common materials steel self dumping hoppers are used for include:

- Fluid substances or wet loads

- Recycling material

- Paper

- Aluminum cans

- Construction debris

- Plastic

Available Hopper Models

Galvanized and stainless steel hoppers specifications vary depending on your particular application and are highly customizable. Basic specifications of our standard steel hoppers include:

- Volume capacity ranging from 1/8 cubic yard to 10 cubic yards

- Load capacity ranging from 2,000 pounds to 10,000 pounds

Galvanized Steel Dump Hopper

A hot dipped galvanized steel hopper allows for excellent rust resistance and corrosion protection. Choose a galvanized hopper if you need to handle waste water, sewage or other materials that may rust other hoppers.

You can safely store these items or dry goods outside, knowing the galvanized exterior won’t be harmed by the elements. Ask about exterior labeling for hazardous material handling.

Always review the specifications of our material choice and your particular material. Even galvanized steel may not be appropriate for every chemical or waste product. Our experts are always available to discuss your material handling requirements, so reach out to our team to receive professional recommendations on the ideal steel choice.

Stainless Steel Dumping Hopper

Austenitic stainless steel offers similar flexibility and durability when it comes to corrosion resistance. These steel hoppers can withstand extreme temperatures, moisture conditions, and corrosive effects, making them suitable options for chemical, food and beverage, as well as other applications.

Self dumping hoppers are versatile, with a wide variety of types in different sizes, shapes, and customization options available to suit a number of different applications. Contact one of our experts today.

Recommended Self Dumping Steel Hoppers:

-

Stainless Steel Hopper

Load Capacity: Capacity Varies Volume Capacity: Capacity Varies Dimensions: Dimensions VaryRead more -

Galvanized Steel Hopper

Load Capacity: Capacity Varies Volume Capacity: Capacity Varies Dimensions: Dimensions VaryRead more -

4T-1/4-680

Load Capacity: 8,000 lbs. Volume Capacity: 2-1/2 cu. yd. Dimensions: 71" x 57-1/2" x 60 1/2"Read more -

4T-3/16-EL-1890

Load Capacity: 8,000 lbs. Volume Capacity: 7 cu. yd. Dimensions: 91" x 96" x 70"Read more

Benefits of Steel Hoppers

Whether you own a manufacturing plant, construction company, metal workshop, or lumberyard, safety and efficiency are two keys to your success that self dumping steel hoppers can help you to achieve. Intelligent engineering and design allows for handling of materials that are corrosive or even potentially toxic.

In addition to making your work site safer, self dumping steel hoppers also help to increase efficiency. It wastes valuable energy if employees have to take out multiple small loads over and over. It saves time and manpower when a self dumping hopper can be loaded up with small loads and then transported to the waste receptacle when full.

Equipment on the job site is often exposed to the harshest of conditions. One of the biggest advantages of stainless steel hoppers is that they are built to be durable and stand up to the wear and abuse that they are subjected to on a daily basis. If you purchase one of our hoppers today, you can count on it continuing to serve you for many years to come.

Stainless Steel Hoppers’ Customization Options

Another significant benefit that Roura self-dumping steel hoppers have to offer is the wide range of customization options. No two work sites are exactly alike; therefore, we offer additional parts and accessories to allow you to design a hopper that best fits your needs.

- Bases: The standard bases we offer include base legs, box tube design, fork entry, and open channel. We can further modify these options to meet your unique requirements.

- Band Cutter: Steel banding must be disposed of at the end of the day, but this can be difficult and dangerous due to the sharp edges. The safest way to dispose of this material is to cut it up into small pieces. A band cutter mounted on the edge of the hopper makes this easy and convenient.

- Casters and Wheels: The ability to roll makes your hopper easier to transport from one place to another. Our wheels and casters come in a variety of materials and sizes. A complete set typically consists of two rigid casters in front and two swivel casters in the rear. However, you can customize your rig combination to suit your needs.

- Covers and Tarps: We offer tarps and covers for our hoppers in various materials for different applications. Vinyl and mesh tarps provide protection from the elements for temporary storage, a steel lid provides maximum security, and a lightweight plastic lid is easy to remove.

- Latches and Chains: Chains secure the base of the hopper to the body and potentially the hopper to the transport. Latches prevent the hopper from dumping the material within until you are ready.

- Release Systems: A mechanical release system is really important to the efficiency of your hopper. When you transport the hopper with a forklift, the release system gives you the ability to unload the hopper without exiting the vehicle or even leaving your seat.

The appearance of your hopper can also be customized with special colors, brand names, or logos. This results in a recognizable look that helps you make a strong impression.

Self-Dumping Hopper Operational Videos

All self-dumping hoppers require a standard forklift to operate. While we design our steel hopper range to include a number of safety features, they still pose safety risks if handled improperly. Thankfully, we offer a collection of operational videos to see first-hand hopper best practices.

Review how to load, secure, lift and dump hoppers with your team members before using a steel hopper from Roura. These convenient videos offer detailed instructions and clear video of proper self-dumping hopper handling.