As a leading material handling equipment supplier, Roura is a respected presence across various industries. For decades we have created custom solutions for the material handling industry, allowing clients to purchase and receive equipment suited to their specific locations and applications.

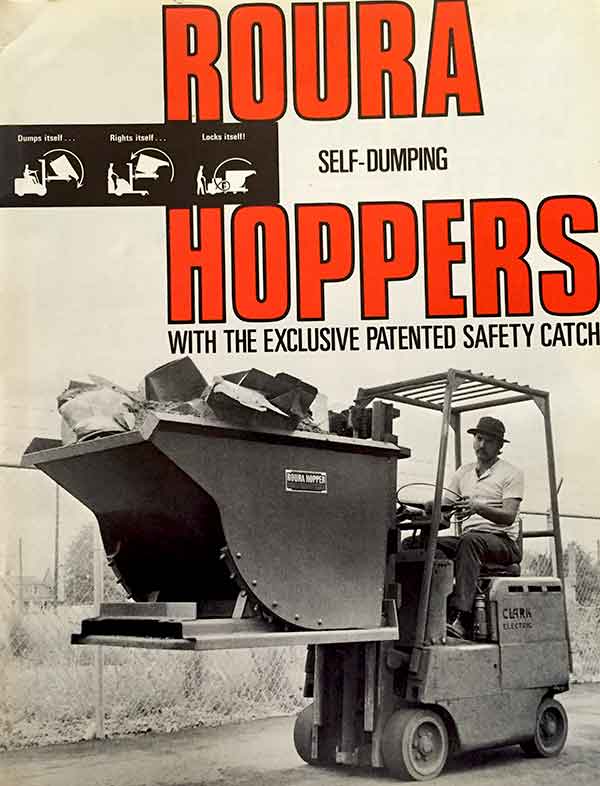

While we are primarily known for the invention and continued production of the self-dumping hopper since the late 1920s, we have been making waves and polishing our sterling reputation for quality and safety for 100 years.

Despite specializing in self-dumping hoppers, Roura also produces an exceptional lineup of quality material handling tools, from rotator boxes, to bottom drop boxes, to stone handling equipment, granite slab handling equipment and products — including A-frames, slab racks, and remnant racks — and so much more. If you’re going to trust anyone with your material handling needs, why not a company with a proven track record of innovation, design, and satisfaction across several industries?

Whether you work in mining, construction, milling, or any number of other notable industries, Roura is here to help with all your material handling needs. The manufacturing industry is almost always in need of current and new, innovative equipment to ensure the safety of the workforce and the continued efficiency of operations.

Material Handling in the Manufacturing Industry

Manufacturers of all sizes struggle to keep up with and overcome the current production environment. From limited floor space to growing product demands and variety and the reduction in labor reliance, it is more important than ever to seek innovative ways to improve production and optimize efficiency, especially in terms of material handling.

Whether a small, specialty operation within the milling industry or a large, global corporation within the mining space, your workforce experiences a unique set of hazards and risks when handling materials. The movement of large stone slabs or the cleanup of metal shavings presents different worker safety obstacles, but the goal is the same, to keep employees healthy.

Our material handling equipment is all created with safety and efficiency in mind. Our hoppers allow for secure storage of waste or excess materials and provide easy dumping mechanisms to ensure worker safety. Our A-frames are made of heavy-duty steel with crossbars and timbers for added security. Additionally, we offer training videos to help you educate your workforce about the correct ways to handle materials and material handling equipment.

Self Dumping Hoppers

The products we are most likely known for are our self dumping hoppers. The tool is a steel box used to store, transport, and dump materials. Each hopper offered by Roura can easily be used with a forklift, and for improved safety, does not require manual dumping.

The primary benefits of using a hopper are found in its ability to help you maintain a clean facility, encourage safety, and promote efficiency. It is usual for manufacturing plants to become cluttered with off-cuts and scraps; leaving these materials on the floor or near machinery can quickly become a hazard. Having hoppers within range of machining and other operations means cleanup is a breeze, meaning hazard risks are reduced. Additionally, by having the self-dumping mechanism and forklift ports, transporting materials is easy.

When it comes to the types of hopers we offer and their applications, we have many options. The most popular hoppers include:

The hoppers vary in size and capacity limits, but our largest can hold up to 10,000 lbs. or between six and 10 cubic yards. All of our hoppers have been used for a variety of applications, including:

- Milling

- Mining

- Construction

- Foodservice industry

- Stone storage

- Waste management

Stone Handling Equipment

When discussing material handling equipment, especially for stone, granite, or marble slabs, it is crucial to select racks and carriers that can hold significant load capacities while maintaining necessary safety features. Our A-frames, granite slab racks, and remnant racks provide just the quality and security you would expect from your handling equipment.

Our A-frames have a load capacity of 12,000 lbs. per side. Built from high-quality steel, using superior welds, the product ships disassembled to reduce shipping costs and make it easier to install on-site. Each of our A-frame products comes with angled timbers, crossbars, and fasteners to ensure safety and security.

Our remnant racks allow for the storage of smaller cut stone products, and we can customize the length and posts to suit your needs. However, the variety of standard sizes we offer should provide suitable options for most operations and area requirements.

Finally, our slab racks provide a durable system for storing bundles of marble, granite, and stone products. Like the remnant racks, slab racks come in various lengths, and each product comes with a set amount of poles. However, we can modify a design to suit your specific storage requirements.

Rotator Boxes

Rotator boxes are another Roura specialty. You can purchase any of our standard models for handling needs up to 3 cubic yards. Beyond that, you will need to contact us for a custom solution.

We offer the strongest build with all of our standard products, but we can modify our standard models to fit your exact specifications. However, before a consultation about custom work, consider the traditional rotator box models we offer.

- Chip tub rotator

- Rugged rotator

- Drum rotator

- Durable rotator

- Gaylord dumper

- Rotator with lid

- Ultimate rotator

- Custom rotator

For most clients, the thing that matters most is the load capacity. While our max capacity is three cubic yards, the maximum weight limit for select rotators is 6,500 lbs. Consider alternative equipment, like hoppers, if you need to hold or transport heavier materials or larger capacities.

Drum Handling Equipment

Drum handling equipment is commonly used in the foodservice, scrap removal, and recycling industries, but it has many applications beyond those three. The fully-welded body, seven gauge steel construction means our drum lifters and tilters are among the most durable products available. With our focus on drum quality, these pieces of equipment are built for routine use.

Additionally, our drum rotators are designed with the same focus on safety as our hoppers and other products. With adjustable side rails and a security chain, the rotator allows for tightening and repositioning. Both security components ensure the device can be turned upside down without falling out of place.

You can also customize your rotator with optional accessories or design changes. All you need to do is contact our design team to discuss your precise needs and specifications. Our standard rotators are 35 inches by 39 inches by 59 inches and have a capacity of 6,000 lbs.

Industries Served

When you work with a material handling equipment supplier, it is crucial to work with a company that understands your industry and needs. Roura Material Handling has been producing material handling equipment for 100 years, and during that time, we have served many industries and manufacturers, including:

- Mining

- Milling

- Construction

- Solid waste management

- Woodworking

- Manufacturing

- Food processing

- Agriculture

Our equipment can handle most dry bulk materials, dry or cold. We exist to serve the above industries and more. We want to help you find a solution to your material handling needs. If you are interested in any of our products or would like to discuss the customization of one of our standard products, call a company representative to finalize the details.