What is a dumping hopper? Dumping hoppers are versatile containers used to store, relocate and dump materials in a number of situations. While there are many styles and designs, the most common option is a self-dumping hopper. These hoppers include forklift pockets to allow for easy lifting and maneuvering with a standard forklift.

It’s important to choose your hopper carefully. Review the specifications to determine the load capacity and materials that are suitably stored in your chosen hopper. At Roura Material Handling, we offer self-dumping hoppers for use in these and other industries:

- Construction

- Food and beverage

- Manufacturing

- Warehousing

- Agricultural

Hoppers can be used to handle raw materials, such as aggregate, or can be used to remove waste debris from a job site. Store scrap metal, glass fragments or food waste in your hopper before hauling it to a larger recycling container at your facility. Hoppers are highly maneuverable, so they’re suitable for separating recyclable materials at moving job sites.

Once you find a suitable hopper design, be sure your employees understand safe handling strategies. Self-dumping hoppers can be workplace hazards if not handled properly, so review operational videos with your team to prepare for safe material handling.

Benefits of Dump Hoppers

Compare dump hoppers with other material handling solutions to see how these tools can streamline your process and reduce waste. Here are some key benefits you can enjoy when you switch to self-dumping hoppers for material handling projects at your facility or next job site:

- Increased safety: Reinforced steel structures reduce the risk of an overloaded hopper incident. Spacious storage containers reduce the risk of materials falling or spilling out of the hopper. The self-dumping feature of our hoppers allows the forklift operator to unload the materials from the safety of the forklift seat.

- Flexible designs: A Roura dump hopper is specifically designed to handle multiple projects. While you can receive a custom hopper for a single project, you can use a standard hopper to handle refuse, scrap metal, recyclable cardboard and other materials.

- Customizable convenience: Don’t let a unique industry need prevent you from using these convenient material handling tools. Work with an engineering and fabricating team to create a custom hopper to fit your industry, business and specific project.

Common Types of Dumping Hoppers

While dumping hoppers are highly customizable, there are a few common types that are worth exploring. Order a single hopper or a bulk order to enjoy low-cost convenience. The most common hoppers are standard forklift dump hoppers. These come in a range of sizes and gauges of steel, but all use the same basic design.

Stainless steel and galvanized steel hoppers are suitable for hazardous material storage. Materials that are highly acidic or would otherwise damage a standard hopper may be safely stored in one of these unique hoppers. Discuss our material requirements before ordering to ensure you receive the right material for safe storage.

Dross and dewatering hoppers include specialized holes to remove liquid from solid waste. These hoppers are used in particular industrial applications, but can also be used in outdoor storage situations. Drain off rainwater easily while still keeping aggregate or other hard materials stored.

90-degree, skeleton and open-side hoppers all offer additional storage and dumping features for your products. These hoppers can handle larger, more uniform items and make it more convenient to dump them.

Dump Hopper Specifications

Roura Material Handling hoppers use 10 and 12 gauge steel with reinforcement for added strength. Continuously welded carbon steel offers a dependable hold. Depending on the size you choose, you can enjoy between 1/8 and 10 cubic yards of storage capacity. Hoppers are rated to hold between 2,000 and 10,000 pounds.

For even more versatility in your material storage and removal tasks, consider adding optional parts. Here are a few common options we offer for your hopper:

- Casters

- Open channel or boxed tube base

- Band cutter

- Auto-latch release system

Casters give you the option of wheeling your hopper around without lifting it off the ground. Alternative bases add stability and flexibility to your hopper. A band cutter makes it easy to cut frustrating metal banding down to size as you load it into your hopper. Finally, auto-latch release systems are a convenient safety addition to any size of hopper.

History of the Dump Hopper

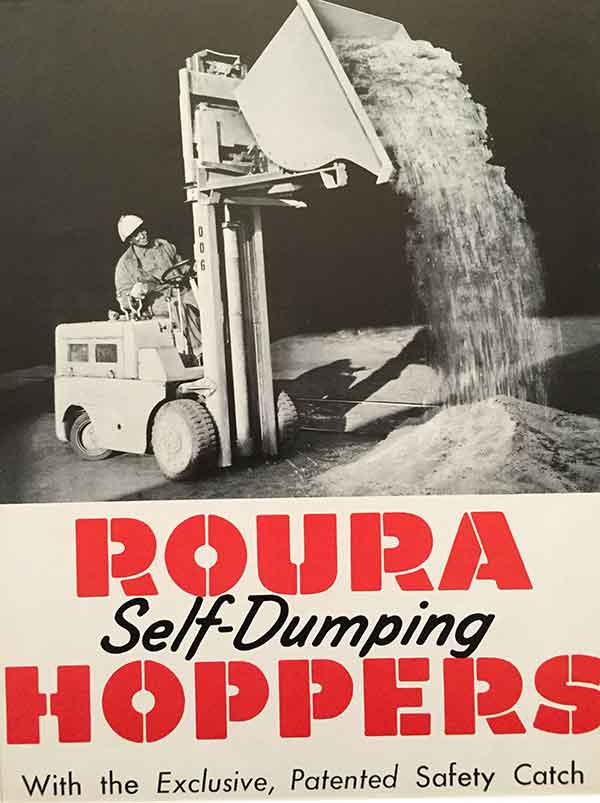

As the original inventor of the dump hopper, Roura Material Handling has a long, proud history of providing dependable solutions to companies in a number of industries. Founded in 1915 in Detroit, our company made a name for itself by fabricating and erecting structural steel.

After years of erecting railroad bridges, buildings and other landmarks in the Detroit area, our company introduced steel boxes and self-dumping hoppers.

Since the 1940s, we’ve specialized in these versatile products. Dependable hoppers that were used for construction projects during World War II became staples of construction, manufacturing and agricultural facilities around the nation.

Dumping Hoppers With Lids

An open-top hopper may make it easy to load your material handling unit, but it also creates additional issues. Prevent wildlife, moisture and UV rays from damaging your materials with a lid or cover for your hopper.

Plastic lids are lightweight and easy to open or close. These durable lids turn a standard hopper into a dumpster or recycling container that doesn’t let water or rodents create a mess.

For even more security, choose a self dumping hopper with a metal lid. Mesh and vinyl tarps are temporary covers to seal up your hopper at the end of the work day.